At present, efficient pulverized coal fired industrial boiler, uses coal power ground by high quality coal dust, featuring the highest thermal efficiency and maximum energy-saving. So the boiler is the first extension project of 'Opinions on the Implementation for top 10 major Energy-saving Projects of 11th Five-year Plan of the State'.

-

Storage Safety

Heat preservation、Temperature measurement

Underground protection

CO2protection

Explosion-proof -

Transportation Safety

Low intensity(0.5)

Stable flow speed(16-30)

Underground protection -

Burning Safety

Automatic burner controlling system

Fire measurement and protection

Membrane panel design

-

Environmental Protection IndexEmission of TSP:≤30mg/m3

Emission of SO2:It can meet the requirements of the local regulations on environmental protection.

Emission of Nox:≤400mg/m3 -

Technical IndexMaterial coal shall be entered into the cryogenic grinding roll to be ground and sorted, after it is dried up to less than 5 per cent by rotary drying kiln, the quality index is the following:

Qnef:≥4500kcal/kg

Vdaf:≥25%

Mmf:≤5%

Aad:≤25%

Percent passing of sieve mesh number of 200:>95%

Combustion Methods

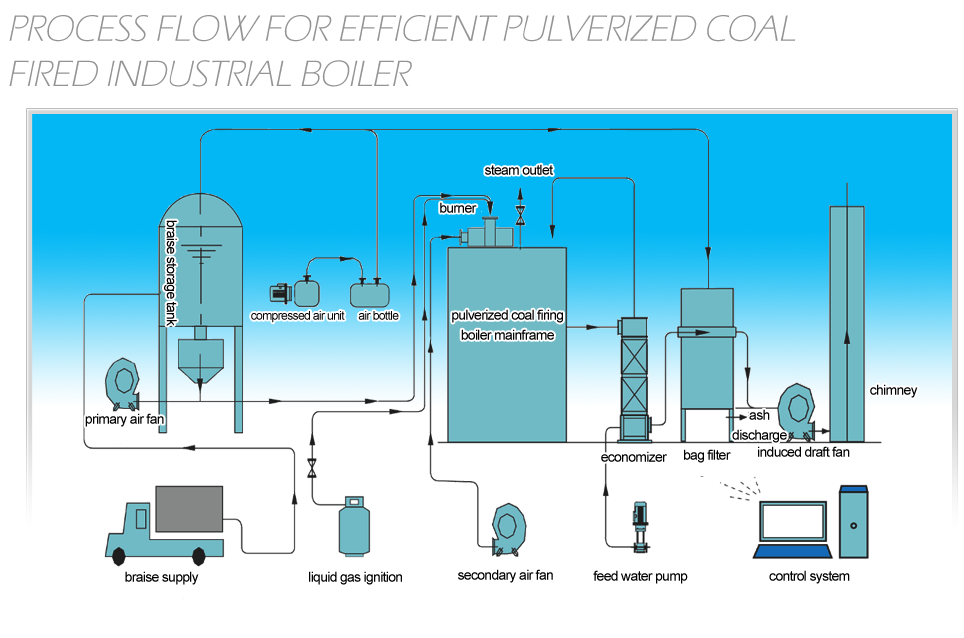

Efficient pulverized coal-fired boiler system consists mainly of

the following equipments: which are braise storage-supply

subsystem, burner subsystem, measurment and control subsystem,

boiler subsystem, bag-type dust remover subsystem, heating power

subsystem, and other equipments, etc. The coal dust, which

conformity with quality, shall be ran into coal dust tower by the

closed tank wagon from coal dust factory. After it is put in

measuring midbin as required, the braise in tower shall be sent to

the pulverized coal burner by the feeder and the wind-power mixing

tube. Firing system is constructed by burner and boiler furnace.

After radiation and heat convection, high-temperature fume,

produced in combustion process, shall enter the bag-type dust

remover. Clean fume, expelled by bag-type dust remover, is blowned

into atmosphere by the induced draft fan, and fly ash, collected

by bag-type dust remover, is expelled by closed system, which

shall be centralized disposed and used. The operation of boiler

system is completed by ignition sequencer and superordination

computer system in common.

-

Fuelbituminous coal, brown coal

-

Heat Efficiency≥87%~92%

-

Combustion Efficiency≥98%