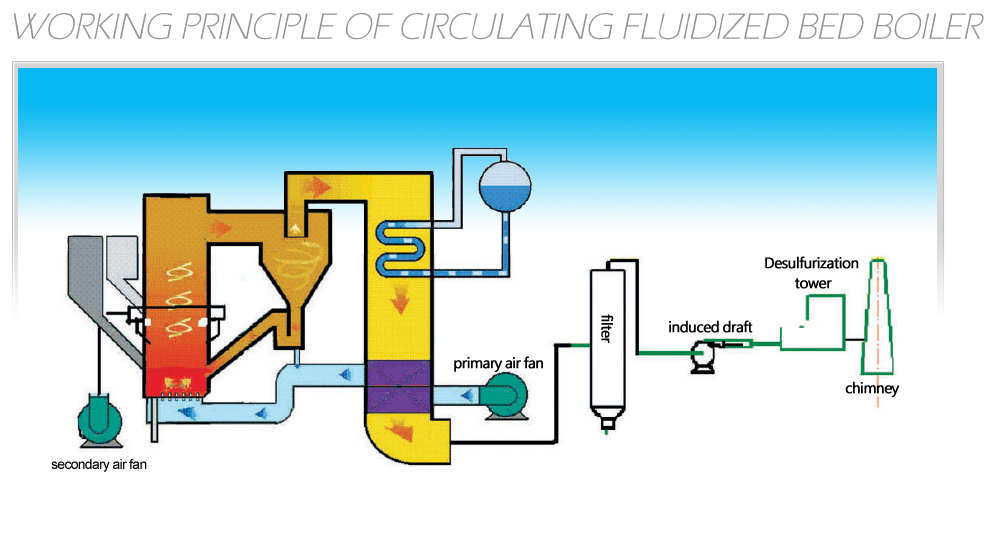

Coal and air are suffciently mixed up and burnt. A large amount of coal particies carried by the smoke enter into the separator. Heavier particies collected by the separator are sent into the main combustion chamber via the recycle device to "recycle" and bum again. Light smoke enters into other parts of boiler and continue the heating. Advanced combustion technology enables the thermal efficiency of this kind of boiler to be over 86%.

CFB is called "clean combustion technology" due to their outstanding performances in terms of efficiency, energy-conservation, low-pollution and low emission of carbon.

Alterate or replace current medium and small coal-fired boilers (furmaces) by adopting technologies such as CFB and coal powder combustion".